Goodbye collapsed pallets, damaged products, and dissatisfied customers.

WHY USE ANTI-SLIP PAPER?

Optimize transport with anti-slip paper

Palletizing and transporting your products are crucial to the performance, efficiency and finances of your business.

Say goodbye to frustration, damage during transport and financial losses. Unstable and unsafe transport belongs to the past. With our anti-slip paper, your goods are stable and safe during transport. The anti-slip coating ensures that the products remain on the pallet during the entire journey from production to the end customer. The paper is used between the layers of products on the pallet and can be supplied in pre-cut sheets or in reels, depending on the type of paper and your specific requirements.

Anti-slip paper

- The main purpose of our anti-slip paper is to stabilize the products on the pallet so that they arrive at their destination in the same condition as when they left the warehouse. Propagroup offers a wide selection of anti-slip interlayers. The choice of paper type depends on your needs and the items to be palletized. We will guide you to the right choice.

- Thanks to the anti-slip treatment of the paper, your palletized finished products remain stable in the warehouse and during transport, guaranteeing trouble-free deliveries and satisfied customers.

- Our anti-slip paper is 100% recyclable and bears the PAP-22 environmental label. The recycling pictogram certifies that the product is fully recyclable and must be properly treated and disposed of.

|

|

|

|

PROPAGRIP

Bestseller: solves most problems.

Recommended use: heavy, slippery or challenging items.

|

|

PROPAGRIP X

Less friction, same function. The friction lining is applied in diagonal strips.

Recommended use: boxes with large contact surfaces, lighter items or similar.

|

Transport and logistics

REDUCE DAMAGE TO PRODUCTS DURING TRANSPORT AND FREE UP STORAGE SPACE

- Minimise pallet collapses and product damage; the pallet can be tilted by up to 50°.

- Reduction of storage space by up to 90% - up to 5,000 sheets per roll.

- Fewer deliveries means an optimised and less resource-intensive goods receipt process.

Process and operations

SIMPLIFY WORK PROCESSES, INCREASE PRODUCTIVITY AND REDUCE DOWNTIME

- Rolls can be replaced continuously outside safety zones, without stopping production.

- The number of reloads is reduced by up to 90%.

- Changes can be made in an instant.

- The fixed pick-up height ensures a fast workflow, every time.

- The problem of lost sheets is eliminated: there is always a sheet ready for picking.

Environment and responsibility

MINIMISE MATERIAL CONSUMPTION AND IMPACT ON THE ENVIRONMENT

- Reduction of paper consumption by up to 40%.

- Reduction of stretch film consumption by up to 30%.

- 100% recyclable and FSC® certified paper.

- Fewer intermediate paper deliveries means reduced CO2 emissions during transport.

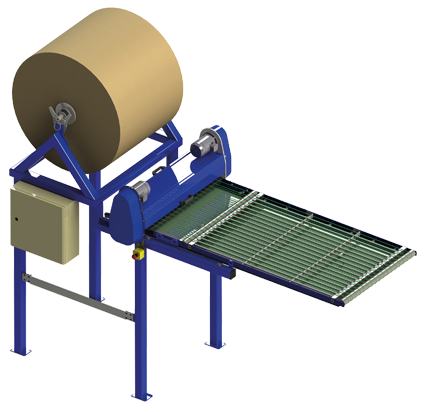

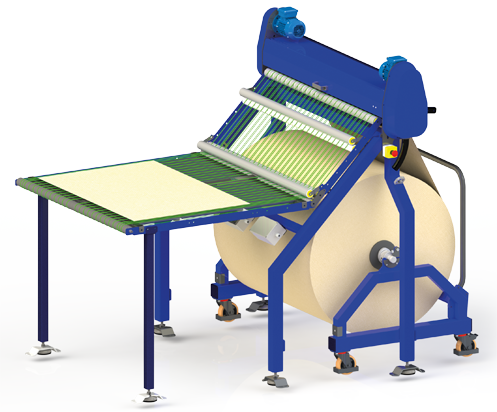

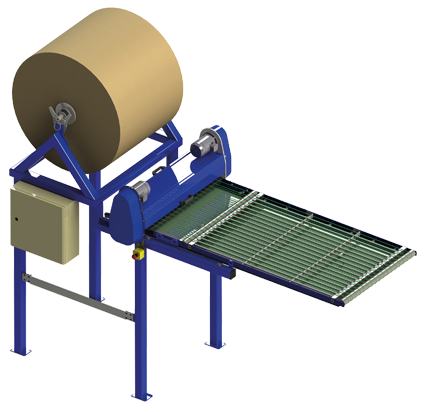

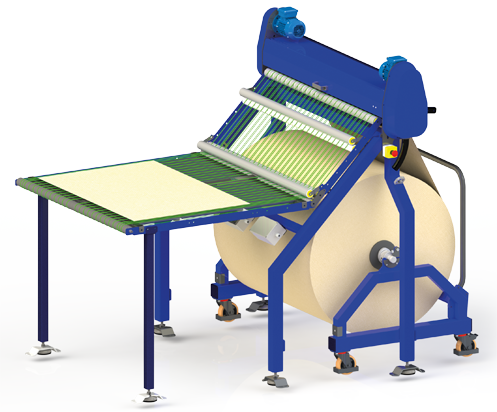

Dispensers

- Simplify work processes and make palletising easy with our fully automatic sheet dispensers.

- The interaction between the sheet dispenser and the anti-slip paper rolls increases efficiency and reduces downtime, pallet failure and transport damage.

- The innovative sheet feeder is easily integrated into the palletising process and guarantees, among other things, a reduced environmental impact, fast workflows and minimal downtime.

Italiano

Italiano Español

Español Français

Français Deutsch

Deutsch